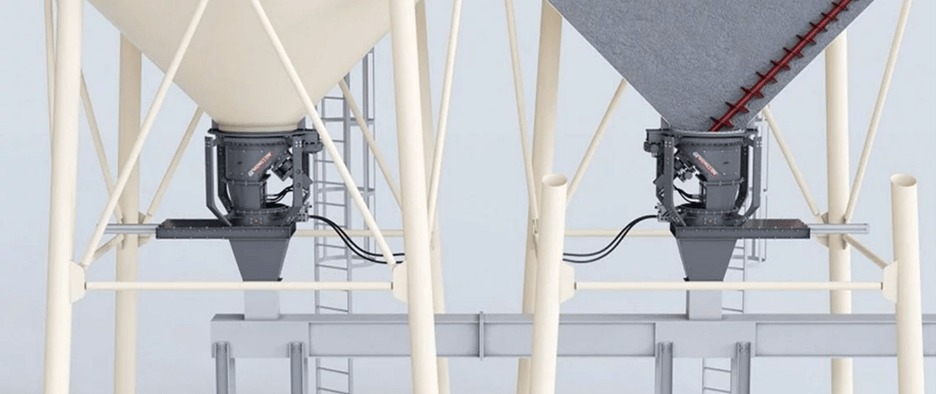

HYDRAUGYRE

The Hydraugyre system uses a hydraulic transmission. An Archimedes screw, driven by a hydraulic motor, sweeps the silo bottom in a 360° rotation to ensure the product is unloaded according to the principle of FIFO (first in, first out). The hydraulic transmission system allows high torque to be transmitted at low speed thanks to Morillon’s Booster start-up system. Its efficiency and ease of use quickly won over its clients. It will enable the Hydraugyre to be launched in a full silo, regardless of the screw’s starting position.

Hydraugyre range:

For silos between 2 and 27 meters in diameter, they offer discharge capacities of up to 600 cubic meters per hour, depending on the product.

Advantages:

- Hydraulic unit installed on the Hydraugyre unloader.

- Very high output without heating up.

- Uses a small quantity of oil.

- Takes up little space.

- Easy to install thanks to its plug-and-play system.