What is the SoliValve® system?

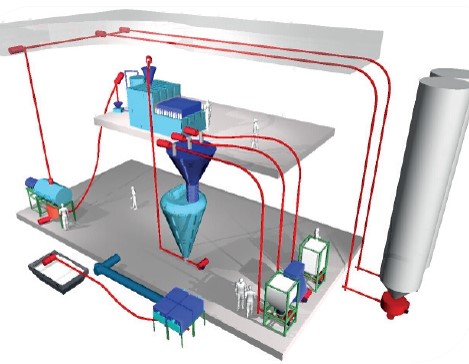

The SoliValve® is an automatic and dust-tight Cone Valve system allowing gravity filling, discharging, and dosing of powders directly from/to any Big-Bag, container, drum, or pouch.

The Cone Valve principle combines an active unit that will feed a process and a passive unit that is fitted onto a recipient to discharge into the process. You can check the principle of operation with an animation here.

SoliValve®250 technology

The SoliValve®250 is a new generation of powder handling system based on the Cone Valve principle.

The SoliValve®250 allows for the first time fully automatic and contained handling of FIBC (BigBags), IBCs (rigid containers), drums, etc., thanks to its universal Passive-SoliValve®. These are compatible with the Active docking units suitable for filling and discharging powders like APIs, Food Additives, Enzymes, Pigments, etc., within all major process industries.

SoliValve®250 is also a very accurate metering device, avoiding using additional devices such as rotary valves or dosing screws to meter your products. Moreover, the SoliValve®250 doses the material vertically from the storage container, allowing the re-closing of the partially empty vessel and changing to the next ingredient without the need to empty the dosing hopper.

SoliValve®250 systems have been installed in over 24 countries worldwide since 2005.

SoliValve®100 technology

The SoliValve®100 is the latest Cone Valve innovation from Visval.

Based on the same principle as its big brother, it allows for the first time fully automatic and contained (OEB5) handling of solids in Pouches, Charge bags, Charge bottles, and small drums/containers/hoppers (1L to 700L) thank a universal passive valve of ø 100 mm. Such containers are used for active ingredients like HPAPIs, APIs, Food Additives, Enzymes, Pigments, Metal powders, etc., within all major process industries.

The aperture of the SoliValve®100 is controlled by a highly accurate step motor and a play-free ball screw, allowing opening increments down to 0.1 mm.

This exceptional positioning provides incredible dosing accuracy for a wide range of weights, starting at a few grams to hundreds of kilos. With adequate scale resolution, the SoliValve®100 can reach a dosing accuracy of +/- 1g.The containment performance of the SoliValve®100 system has been tested and validated for OEB5 (<1µg/m3) applications by an independent institute (SMEPAC test).

Benefits of the SoliValve® versus other powder transfer systems

Powder handling industries rely on conventional technologies like split butterfly valves, dosing screws, and old cone valve systems. However, these have limitations in functionality and performance.

The SoliValve® system, the optimum solution for gravimetric powder discharging, is the perfect answer to traditional compromises. It combines automatic docking, contained discharging, and acccurate dosing capabilities and is not dependent on one type of container. The Passive-SoliValve® can be accommodated to almost any rigid or flexible recipient type.

Split Butterfly Valves cannot discharge difficult flowing powder as they are “passive” discharge systems. They cannot achieve accurate dosing and are very sensitive to mechanical abuse, given their highly mechanical construction. Old Cone Valve systems are not fully tight and generate powder spillage when moving the IBC, the infamous “ring of death” as known in the industry.

Dosing screws offer good and repeatable accuracy but are limited by the size of the “chamber”, defined by the pitch and the diameter of the screw. It means that a dosing screw is usually ideal only for a defined weight and speed range. For an extensive weighing range, 2 or more sizes of screws would be needed. Furthermore, the dosing screw is not a containment device, and its cleaning is complicated, as the screw must be dismounted to gain access to the auger.

The SoliValve® controls its opening to an accuracy of 1mm (0.1mm for the SoliValve® 100), allowing high dosing accuracies for a wide weighing range, from a few hundred grams to over 1’000kg.

The SoliValve®250 is designed to be used with IBCs, FIBCs, and drums from 25 up to 1’500kg.

The SoliValve®100 is designed for active ingredients, vitamins, and highly potent APIs. These powders are usually stored in smaller recipients, from <1kg to 50kg. Some applications see the SoliValve®100 being used on larger IBCs/hoppers and big bags up to 1000 Liters.

Key Benefits of the SoliValve® Cone Valve technology:

- Fully automatic and dust-tight connecting & disconnecting of IBCs and FIBCs

- Controlled discharge and filling of poor and free-flowing powders

- Accurate / repeatable dosing directly from any FIBC or IBC with Passive-SoliValve®

- Fluidisation function to prevent bridging and segregation of powder.

- Partial discharging and undocking of IBCs, FIBCs and drums

- Removal of partially emptied/filled Big Bag and IBC without residual powder or dust.

- Fail-safe shut off of material.

- Available in a filling version as well, allowing customers to operate all their powder handling processes using one standardized docking system for all their mobile powder storage vessels

- The same Passive-SoliValve® can be used for discharging and filling.

- No requirement for proprietary IBC

- 2 sizes of cone valves: 250mm and 100mm.

SoliValve® is the answer to the limitations of all conventional docking systems currently available. It is designed to be used with IBCs, FIBCs, drums, and pouches from <1kg up to 1’500kg.