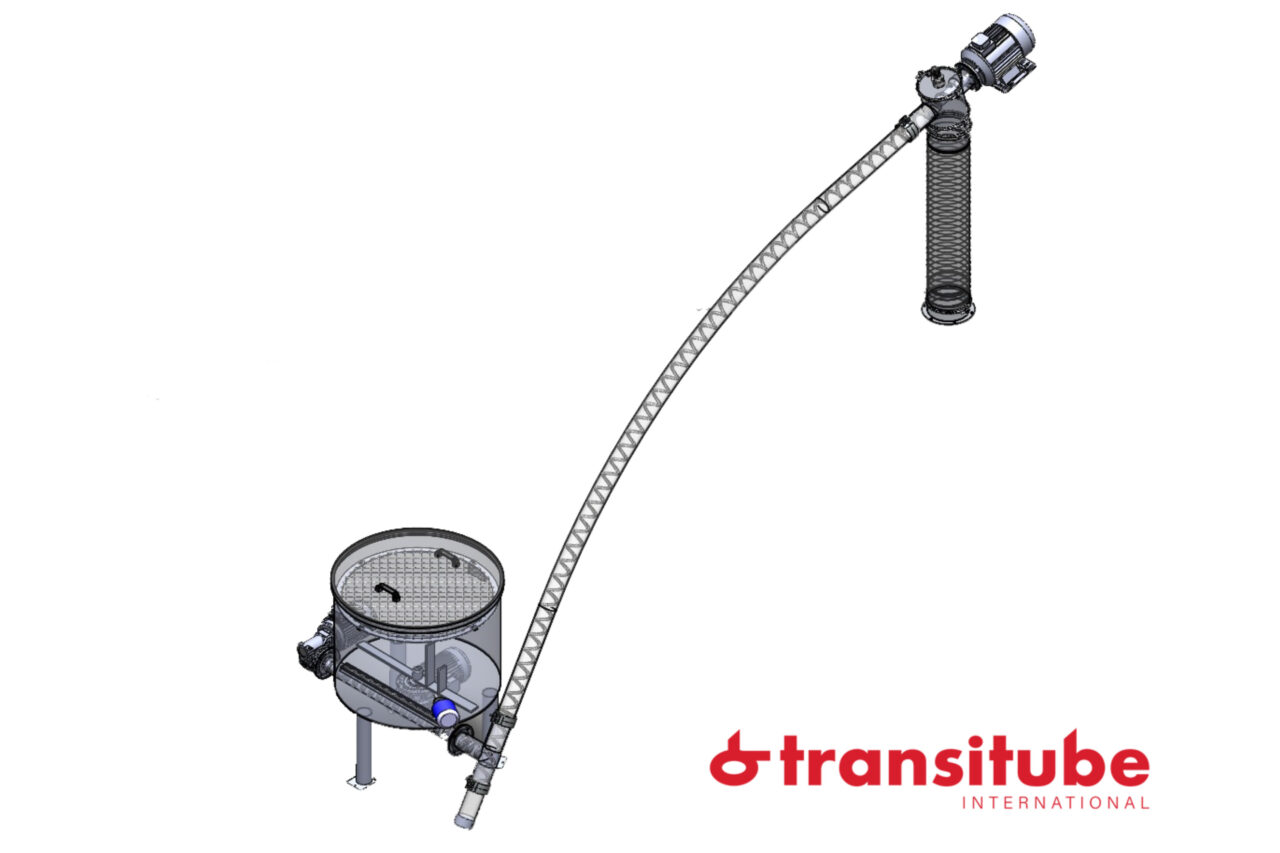

Transfer System for non-flowing products: Efficient Powder Conveying Solution

The transfer system from Transitube is an advanced solution designed for transporting challenging powders and aggregates in industrial environments. It utilizes innovative Transitube technology, featuring a stainless-steel flexible spiral that rotates within a conveying tube. This rotation creates a material ring that moves without air or dust, using the centripetal force and called “Transitube effect”, safeguarding the product from external contamination or particle size reduction. In a non-flowing product configuration, this technic is combined with a Transitube anti-bridging and force-feeding equipment to constantly fill the tube.

Key Benefits:

- Productivity: Streamlined powder transfer increases overall efficiency.

- Reduced Labor Intensity: Automation minimizes manual handling.

- Cleanliness and Safety: A dust-free environment ensures safety and hygiene.

- Energy Savings: Optimized operation reduces energy consumption.

- ATEX Compliance certified by INERIS: Designed for explosive atmospheres.

- 100% Food Standard: Meets stringent food safety regulations.

Applications of the Anti-bridging Transfer Auger

The Transitube system is ideal for extracting ingredients from various sources such as silos, big bags, hoppers, mixers, and sieves. Its flexibility allows it to effectively handle challenging products that may cause blockages or “bridging” in both dry and wet environments.

The transfer equipment assembly operates using the Transitube® system, ensuring powders and aggregates are conveyed without air or dust, thereby protecting them from contamination and damage.

Equipped with a flat bottom for easy integration, this equipment features a slow-rotating de-bridging paddle that effectively breaks up blockages, ensuring a continuous supply of material to the auger downstream.

The Transitube system offers an innovative, efficient, and hygienic solution for the industrial transport of challenging powders and aggregates. Its design prioritizes flexibility, cleanliness, and operational efficiency, making it a valuable addition to any production environment.