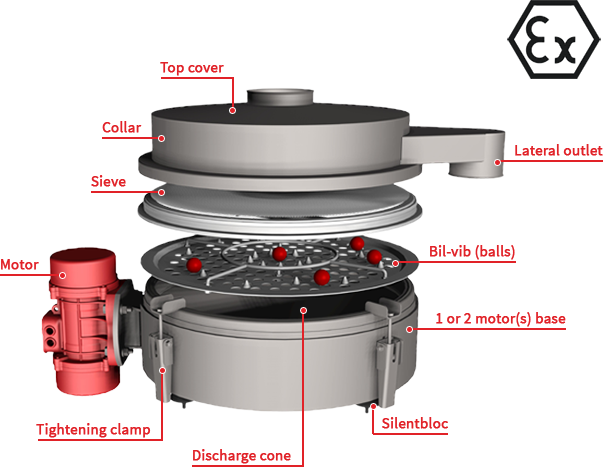

The round vibrating sieve CS allows the removal of foreign materials of agglomerates in small percentages (<5%) for any dusty products or aggregates and for safe filtration of liquid/solid.

FLOW:

From 10 kg/hr to 50 T/hr.

INDUSTRIES

- Food

- Pharmacy

- Cosmetics

- Chemistry

- Paint

- Metallurgy, etc.

APPLICATIONS

- Milk powder

- Flour

- Crystal sugar

- Cocoa

- Dextrose

- Starch

- Metal powder

- Pigments

- Active ingredients, etc.

OUR EXPERTISE: « TAILORED DESIGN »

- Stainless steel 304/316L

- Electro-polished, brushed, polished mirror.

- With or without a lateral outlet

- One-piece collar, open with top cover, height, etc.

- Inlet and outlets diameters: unique or standard

- Inlet and outlets: central or off-center

- Handless, lifting lug, manholes, orientation guide, etc.

RANGE

6 diameters are available:

- CS 45 = 0.15m²

- CS 60 = 0.31m²

- CS 90 = 0.63m²

- CS 120 = 1m²

- CS 150 = 1.65m²

- CS 180 = 2.5m²

HIGHLIGHTS

- Modular design with one or two counterweighted motors

- Dismantling without tools

- All parts in contact with the product are removable.

- No retention area

- Optimal containment and tightness

- Unlimited settlements

A PROGRESSIVE MACHINE

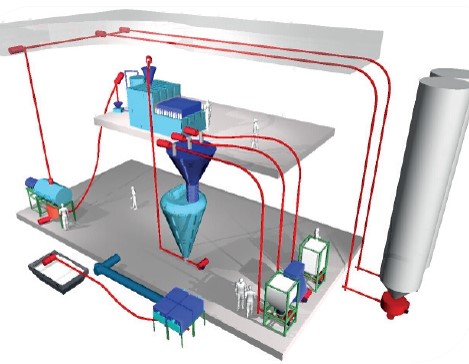

CS 60 PT: for the screening of powders in a dilute phase transport extraction.

CS 60 BAG: specially developed for the safety screening of material in bags of 25 kilos.

OPTIONS

- Mobile support steel/stainless steel

- Ultrasound declogging system

- Declogging system BIL-VIB (balls)

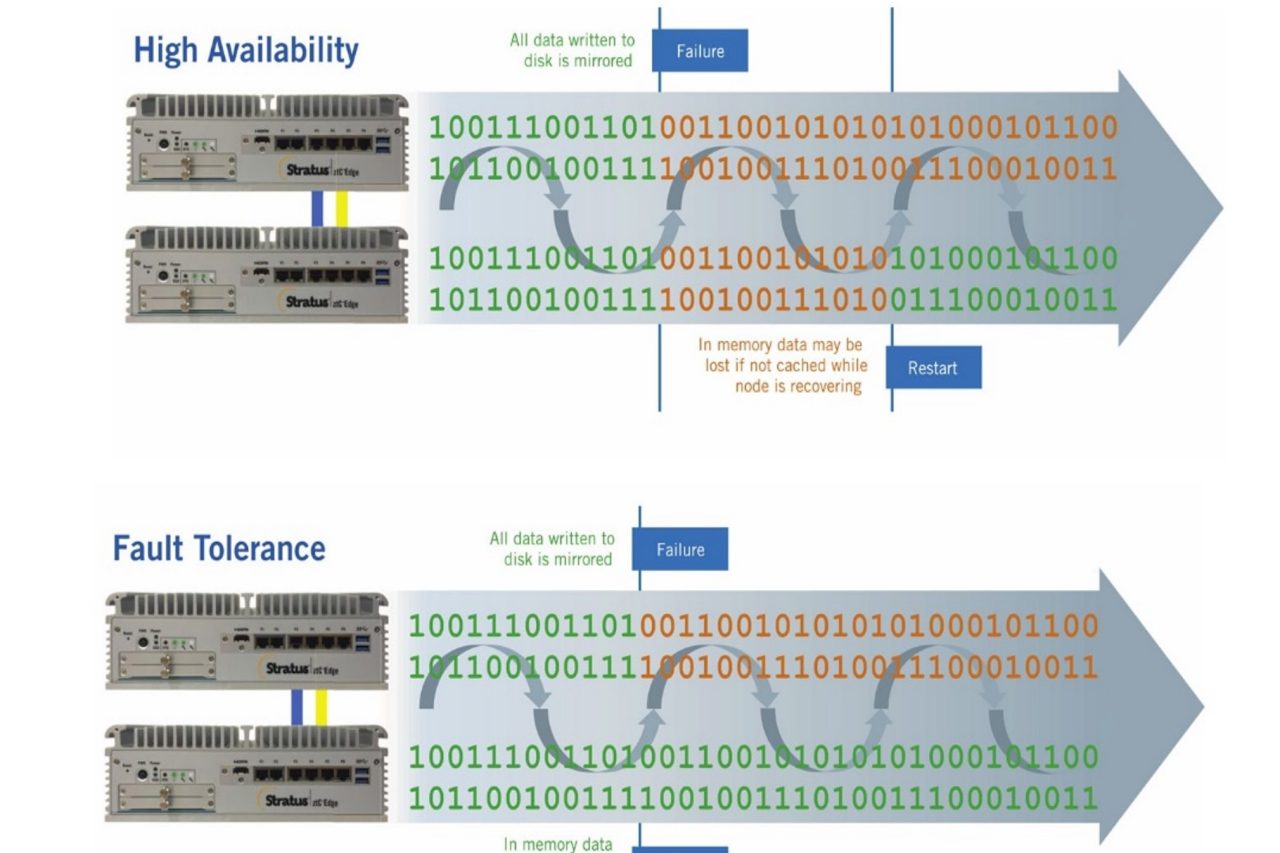

- Certificates ATEX/FDA

- Painted or stainless-steel bas

- Painted or stainless-steel motors

- Wash nozzles

- Polished finish, electro-polished,

mirror-polished

A PROGRESSIVE MACHINE

CS 60 PT: for the screening of powders in a dilute phase transport extraction.

CS 60 BAG: specially developed for the safety screening of material in bags of 25 kilos.