POWDER TRANSFER SYSTEM

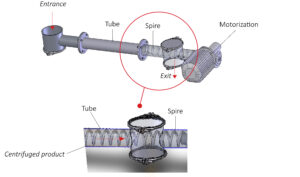

The Transitube consists of a flexible polyamide tube that is 100% bio-sourced, a spiral, and a motor.

The powdery substance is introduced gravitationally at the entry of the spiral is immediately centrifuged by the rotating spiral against the transfer tube wall. A vortex effect appears at around 400 revolutions per minute and becomes more significant than the mechanical displacement starting from 700 revolutions per minute.

The powdery substance thus forms a dynamic fluid layer, within which the spiral is guided throughout the entire path. The quantity of powdery substance introduced into the device is determined by a dispenser.

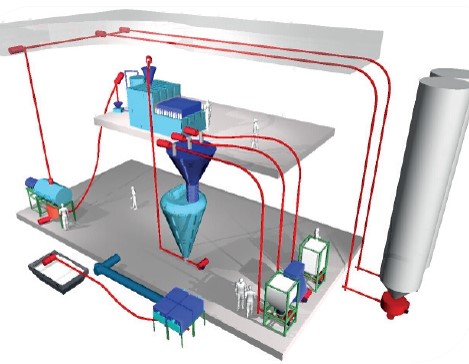

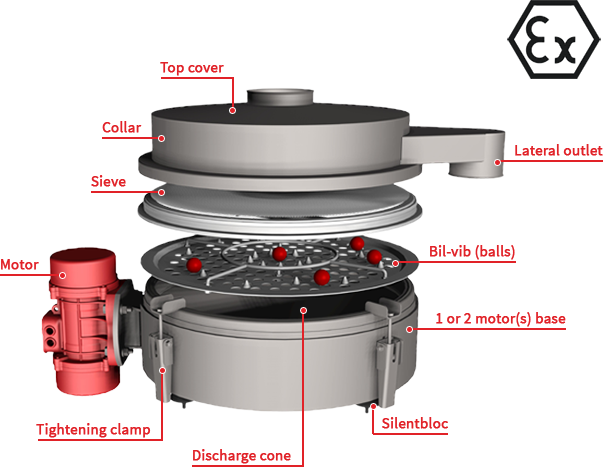

Around the Transitube, we build complete chains consisting of equipment ensuring functions such as weighing, emptying/loading, grinding, storage, sieving, mixing, and bagging.

- Closed and sealed system

- Manufacturing and materials are chosen according to your industry.

- Respect for product integrity

- Regular flow and load start.

The Transitube 14 makes it possible to convey powders and aggregats with a “simple flow”.

It is suitable for center to center or elevation distances of 20 meters. Beyond that, it easily adapts to systems with relays. Its flexibility and direct power supply allow it to reduce space requirements.

Storage and distribution of fluctuating flow products.

The Transitube T12 with its distributor, positioned under hopper, under silo, under big-bag… ensures the correct loading of your material and guarantees the expected flow rate with a volumetrice precision of +/- 100 g.

This T12 range is often intended for a cluttered factory environment and/or a material exhibiting delicate behavior.

Storage and distribution of non-free flowing products.

The feeding of powders, chips, scales in hopper storage, silos or bulk bag.. is sometimes complicated by bridges, chimney hole forming or compacted product blocks.

The 11 series is designed for the handling of difficult products. It integrates anti-bridging or feeding systems, with low rotation to ensure a constant product charging with throughputs up to 20 m3/h.